Search Products

Metal

Complete System for Corrosion Protection of Insulated Surfaces (CUI)

August 2, 2018

PRESS RELEASE

Complete System for Corrosion Protection of

Insulated Surfaces (CUI)

Corrosion under insulation (CUI) is a serious and often dangerous threat to industrial facilities containing insulated piping. The problem arises when condensation or leakage allows moisture to become trapped between the surface of the pipe

Corrosion under insulation (CUI) is a serious and often dangerous threat to industrial facilities containing insulated piping. The problem arises when condensation or leakage allows moisture to become trapped between the surface of the pipe

and the insulation, encouraging corrosion to begin. To make matters worse, insulation also hides the corrosion, making it more difficult to detect and resolve. This can lead to irreversible damage on piping, resulting in potential leaks or even life-threatening explosions of pipes that handle hazardous fluids. The seriousness and secrecy of CUI should make it a top priority to have diligent inspection and preventative measures in all industries dealing with insulated metal surfaces.

Cortec® Corporation, the global leader in VpCI® Technology, offers two forms of treatment that reduce the risk of experiencing CUI and its accompanying problems. CorroLogic® CUI Inhibitor and CorroLogic® CUI High-Temp Inhibitor provide protection for lower temperature and higher temperature pipes, respectively, and are helpful additions to a CUI preventative maintenance plan.

For relatively cooler pipes that experience temperatures up to 338 °F (170 °C), CorroLogic® CUI Inhibitor offers an innovative solvent-based, injectable corrosion inhibitor that protects against CUI on new and existing insulated pipes. CorroLogic® CUI Inhibitor contains Vapor phase Corrosion Inhibitors that can be injected into new or existing insulation. The Vapor phase Corrosion Inhibitors travel throughout the void spaces of the insulation in order to reach and protect the metal surfaces underneath. CorroLogic® CUI

Inhibitor is long-lasting and protects in both wet and dry cycles. It can be used to protect piping made of carbon steel, copper, and brass.

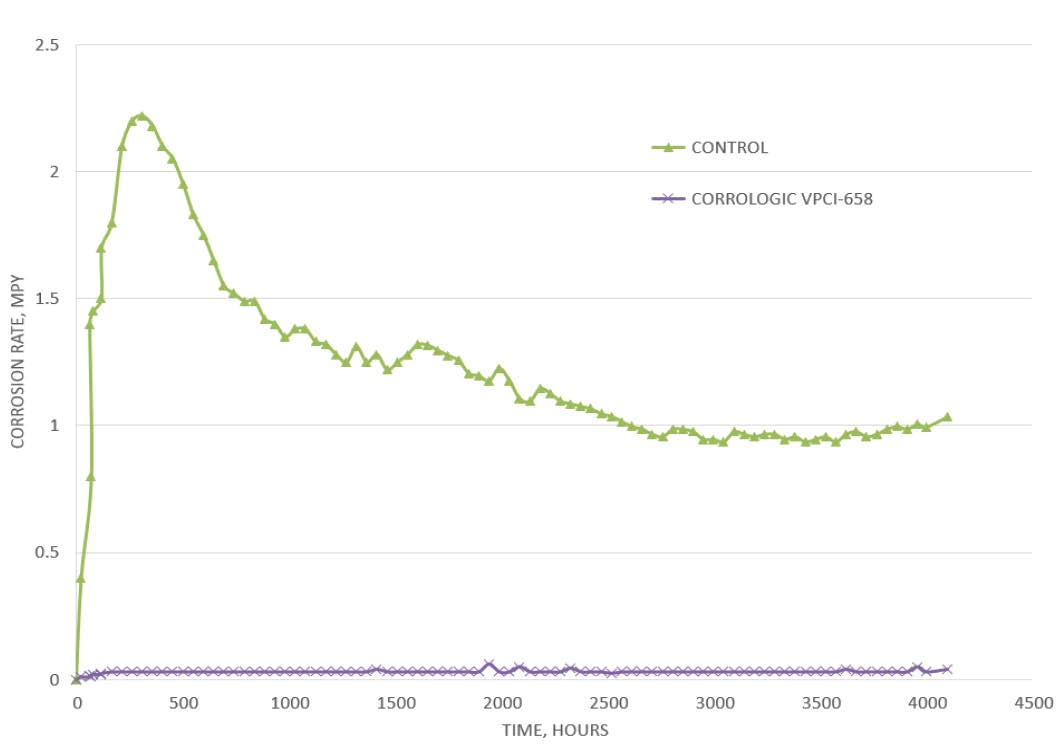

In testing of CorroLogic® CUI Inhibitor where an ER (electrical resistance) probe was used to monitor corrosion rates, the sample containing CorroLogic® CUI Inhibitor demonstrated a steady corrosion rate near zero for 4,000 hours of testing, while the control sample peaked and stabilized at a rate of approximately 1 MPY (see Figure 1). A pipe treated with CorroLogic® CUI Inhibitor also showed very little corrosion upon visual inspection after 210 days in corrosion testing (see Figure 2).

Figure 1: Corrosion Rate of CUI Samples Using ER Flush 10 Probes1

ER (electrical resistance) probe corrosion readings over 4000 hours of testing.

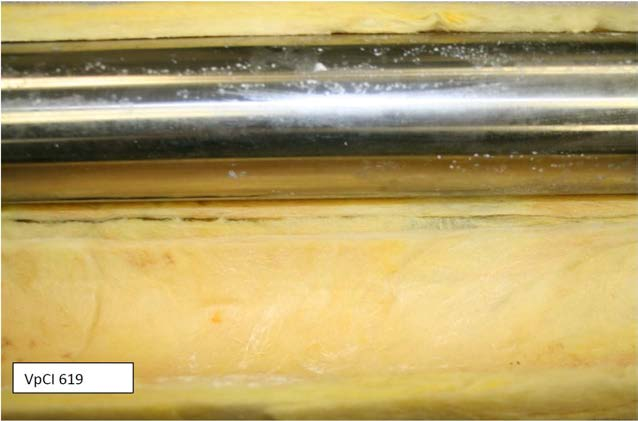

Figure 2: Pipes after 210 Days of Corrosion Testing1

CorroLogic® CUI Inhibitor was applied to the bottom pipe.

For pipes experiencing temperatures up to 1100 °F (600° C), Cortec® offers a water-based corrosion

inhibitor called CorroLogic® CUI High-Temp Inhibitor. CorroLogic® CUI High-Temp Inhibitor can

extend the life of piping and insulation in refining, petrochemical, and marine environments thus

minimizing replacement material and labor costs. The product is non-corrosive and non-flammable, so it

can be applied and used safely in widely varying conditions. A typical and extremely useful application is

the protection of insulated steam or hot oil pipelines made of carbon steel or cast iron.

Figure 3: Unprotected pipe, after 240 hours of testing in high temperature conditions with regular

chloride injection.2

Figure 4: Pipe protected by CorroLogic® CUI High-Temp Inhibitor after 240 hours of testing in

high temperature conditions with regular chloride injection.2

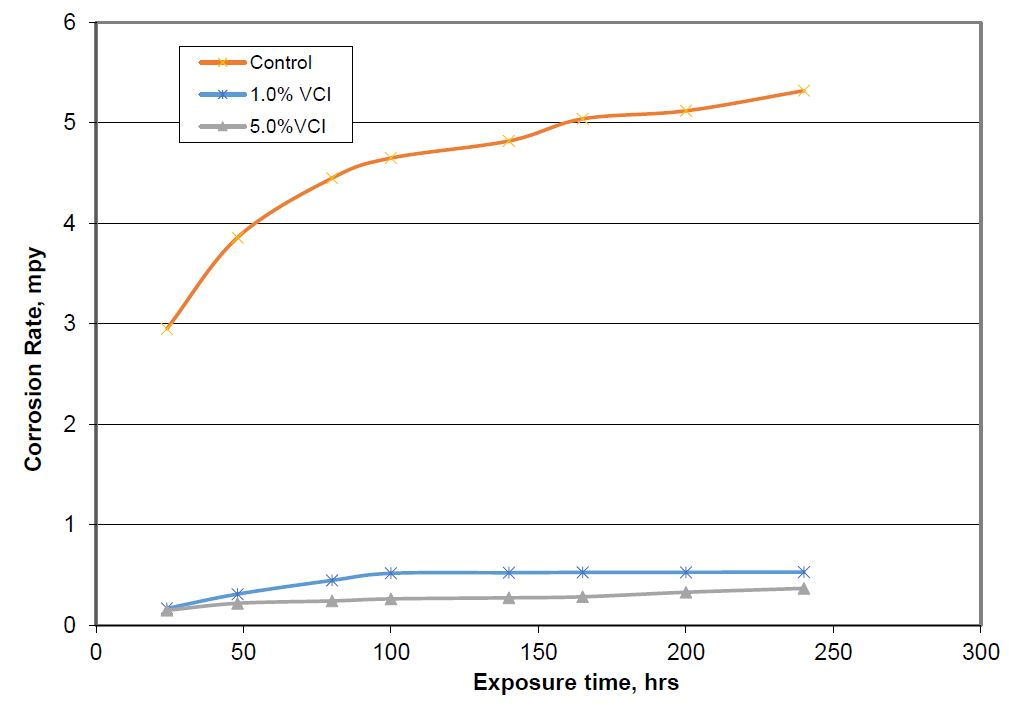

Figure 5: Corrosion Behavior of API 5L X65 Mild Steel Pipe at 220 °F (104 °C)2

Corrosion behavior of steel pipes in boiling chloride water solution (200 ppm). Corrosion rate (mpy) of

untreated control (orange) versus samples treated with 1% CorroLogic® CUI High-Temp Inhibitor (blue)

and 5% CorroLogic® CUI High-Temp Inhibitor (gray).

To discourage CUI in high temperature applications, CorroLogic® CUI High-Temp Inhibitor should be sprayed on the inside of insulation before it is wrapped around new pipes or other metal surfaces that need to be insulated. It can also be used on existing pipes when routine maintenance encounters damaged insulation and/or uncovers corrosion beneath the insulation. If the pipe is still in working condition, it may be cleaned and wrapped in new insulation treated with CorroLogic® CUI High-Temp Inhibitor to provide future protection. Possible applications for CorroLogic® CUI High-Temp Inhibitor include insulated piping or exhaust manifolds in:

To discourage CUI in high temperature applications, CorroLogic® CUI High-Temp Inhibitor should be sprayed on the inside of insulation before it is wrapped around new pipes or other metal surfaces that need to be insulated. It can also be used on existing pipes when routine maintenance encounters damaged insulation and/or uncovers corrosion beneath the insulation. If the pipe is still in working condition, it may be cleaned and wrapped in new insulation treated with CorroLogic® CUI High-Temp Inhibitor to provide future protection. Possible applications for CorroLogic® CUI High-Temp Inhibitor include insulated piping or exhaust manifolds in:

• Power Plants

• Refineries

• Ships

• Offshore Rigs

• Other Industrial Facilities

In either case, the preventative measures taken to protect insulated pipes and metal surfaces against CUI offer both long and short term benefits. In addition to increasing overall plant safety by reducing dangerous corrosion-related failures, protecting against CUI with CorroLogic® CUI Inhibitor or CorroLogic® CUI High-Temp Inhibitor also helps reduce the frequency of maintenance and repair related to CUI. As with so many other preventative maintenance tasks, a little maintenance now protects against many headaches and repair costs later.

To learn more about CorroLogic® CUI Inhibitor, please visit:

http://corrologic.com/corrologic-cui/

To learn more about CorroLogic® CUI High-Temp Inhibitor, please visit:

http://corrologic.com/corrologic-cui-high-temp-inhibitor/